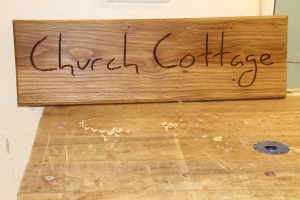

House sign

A neighbour had asked me to make a house name sign for a cottage just down the lane from home.

A previous blog describes the design and making of the board, but I was a little concerned when it came to fitting .

The client had wanted the board mounting over the front door under a small canopy type of porch. My concern that to fit in that position I would have to drill in to a lovely stone lintel.

To drill in to the stone was not a problem for my big sds drill, but if the client wanted to change the board at a later date, there would be four screw holes which I felt would be unsightly.

I considered various options, a french cleat above the lintel would raise the board too high relative to the lintel. Wooden laths coming down from the roof structure of the canopy would look clumsy.

I needed something that would hold the width of the board to reduce the risk of the board twisting, but at the same time allowing me to attach the board on the lintel.

installation

The solution to the lintel problem was to put a pair of 25mm square section oak laths across the width of the board, screwed from the back in to the board to provide some resistance to the board twisting. I then made some stainless steel brackets to attach to the laths and projecting 20mm above the top of the board to allow attachment of the structure to the wall above the lintel.

The holes were drilled and plugged and the sign attached. Unfortunately the face of the render was not flush with the front of the lintel so was packed out using stainless steel screw cups.

All the fittings used to attach the laths to the sign and attaching the brackets were A4 marine grade stainless steel. Obviously to prevent any rust, but also to minimise any chance of a steel screw marking the wood in the sign.

Get in Touch

Call 07710 888611, or email mrhwoodwork@outlook.com.